The Ecomax® Gas Generator Sets

A unique cogeneration concept for greenhouses. With many years of experience in the greenhouse industry, we present cogeneration solutions with the same positive features that have made our modular plants so successful. The ECOMAX® GH modular package solution combines characteristics such as versatility, modularity and compactness with high energy efficiency performance. Thanks to its great flexibility,

A unique cogeneration concept for greenhouses.

With many years of experience in the greenhouse industry, we present cogeneration solutions with the same positive features that have made our modular plants so successful. The ECOMAX® GH modular package solution combines characteristics such as versatility, modularity and compactness with high energy efficiency performance.

Thanks to its great flexibility, Ecomax® can be run at different speeds from 100% of rated power to 50% of plant potential, in order to optimize the produced energy carriers.

Vertical scalability enables coverage of the entire power range. Horizontal scalability, guaranteed by a multiple module solution, especially suited to large plants, enables production to be sustained in reduced load conditions or during scheduled production stoppages. Both an outdoor and an indoor modular solution are available to cater for each specific design requirement and, in particular, to facilitate interconnection with existing plant systems. We are your ideal partner for ‘turnkey’ construction of your cogeneration plant, from design to servicing. The Ecomax is the perfect one stop for the entire life cycle of your plant.

Advantages:

- Top-Quality products, made entirely in-house.

- Outdoor and indoor solutions.

- No building permits.

- Major reduction of on-site assembly.

- Easy relocation and scalability.

- Easy control and interconnection with existing systems.

- Shorter delivery time.

- Easy import procedures.

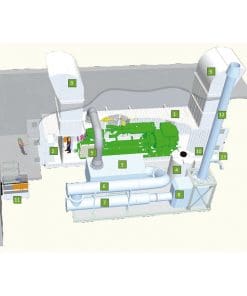

- ECOMAX® : containerized engine + gas train + acoustic enclosure, all in one

- Control panel: used to control and manage the total solution

- Exhaust gas purifier: for the production of clean CO2

- Urea tank: storage of urea for use in the exhaust gas cleaning system

- Urea injection: injector of Urea into the exhaust gasses in order to reduce the NOx content in the exhaust gases

- Exhaust gas cooler: this is used to cool exhaust gasses in order to recover thermal energy

- Exhaust gas condenser: this is used to cool exhaust gasses in order to recover thermal energy bringing the exhaust gas temperature to a value which is suitable for CO2 fertilization in the greenhouse

- Filter: to reduce particles from the exhaust gas before being blown into the greenhouse

- Ventilation ducts: for ventilation and combustion air

- Exhaust gas cleaning system control and guarding panel: to control, manage and guard the exhaust cleaning system

- Oil skid: for storage of waste and fresh lubrication oil

- Exhaust gas stack: for the release of exhaust gas when not used in the greenhouse

- CO2 valve: this is the point where the clean CO2 is taken for delivery to the greenhouse when needed

| ECOMAX 6 GH | ECOMAX 10 GH | ECOMAX 14 GH | ECOMAX 18 GH | ECOMAX 24 GH | ECOMAX 30 GH | ||

| Electrical power | kW | 637 | 1067 | 1487 | 1817 | 2435 | 3047 |

| Gas volume | nm3 / h | 163 | 274 | 364 | 439 | 586 | 732 |

| Engine type | GE Jenbacher J312GS-D05 | GE Jenbacher J320GS-C05 | GE Jenbacher J420GS-B305 | GE Jenbacher J612GS-F07 | GE Jenbacher J616GS-F07 | GE Jenbacher J620GS-F07 | |

| Number of cylinders | PC | 12 | 20 | 20 | 12 | 16 | 20 |

| Empty weight | Kg | 7700 | 13900 | 16300 | 23400 | 29400 | 33500 |

| Total weight | Kg | 8200 | 14400 | 17000 | 24400 | 30400 | 34600 |

| Generator type | Leroy-Somer LSAC 49.1L9 | Stamford PE734E | Leroy-Somer LSA52.2L70 | AVK DIG130i/4 | Leroy-Somer LSA54XL95 | Leroy-Somer LSA54ZL105 | |

| Type rating | kVA | 785 | 1710 | 2005 | 2500 | 3650 | 4000 |

Be the first to review “The Ecomax® Gas Generator Sets”

You must be logged in to post a review.

Reviews

There are no reviews yet.