Screen System

In the construction of a glasshouse, a good shading installation is indispensable. Shades control the climate, benefiting the products’ quality. Such an installation can be highly cost-efficient in energy consumption. We supply a comprehensive range of shade cloths; naturally tailored to the customer’s requirements and his crop choice. We supply energy-efficient, heat-resistant, blackout and assimilation shades.

In the construction of a glasshouse, a good shading installation is indispensable. Shades control the climate, benefiting the products’ quality. Such an installation can be highly cost-efficient in energy consumption. We supply a comprehensive range of shade cloths; naturally tailored to the customer’s requirements and his crop choice. We supply energy-efficient, heat-resistant, blackout and assimilation shades.

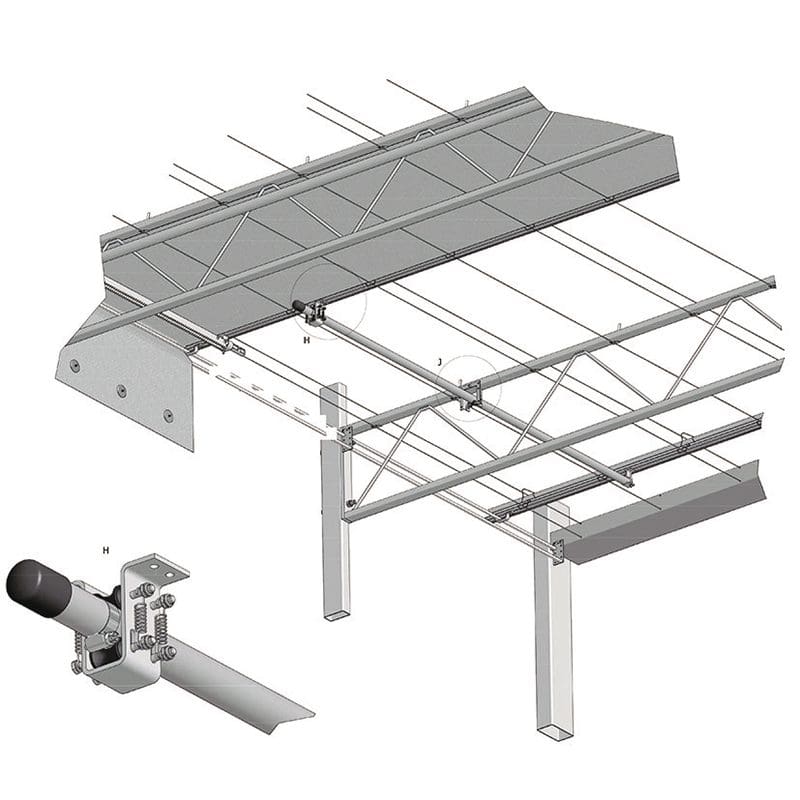

We draw a distinction among two shading systems:

• Push-Pull system

• Pull-Wire system

The advantage of the Pull-Wire system is its ability to allow maximum light through, unlike the Push-Pull system’s Push-Pull rods. On the other hand, the Push-Pull system exerts less force on the gables, which is an advantage when working with different kinds of shades. For both systems, we supply a complete range of parts, such as wire guides, screen profiles, end fixation plates, anti-slip brackets, suspension bracket and truss clamps. We stock the majority of these parts in our own warehouse facility. We supply complete shading installations, including cloth from leading cloth suppliers and the drive mechanism (rack and pinions and motor reductors).

In the Pull-Wire system, a drive tube with wire tensioners, on which steel cables are coiled and uncoiled, provides the horizontal movement of the screen profile between the profiles. The cloth on the wire bed is fastened to the screen profile that moves between the profiles. To provide an energy-tight seal for a shading installation, delay units (slip joints) are mounted under the shading profile. This slip-joint has an adjustable slip tension and compensates glasshouse shrinkage and expansion.

We also have a suitable shading system for glasshouses without profile beams, such as in certain types of foil greenhouses. In such cases, we use a 19 mm. tube as screen profile, to which we fasten the various parts, such as saddle clamps, cloth stoppers, tube clips and wire holders. The drive is identical to that of the Pull-Wire system for glasshouses. In the Push-Pull system, the shading system is operated by racks and Push-Pull tubes. These are in turn connected to the screen profile drawn between the trusses. The diabolo wheel brackets guide the Push-Pull tube. For shading a shorter (end) section, we use a special 4-roll delay unit.

Roll screens are used in the glasshouse wall, the glasshouse roof and the screening wall. The roll screen in walls can fulfil several functions, such as a heat-resistant, energy-saving and blackout function or to limit

light emission. What is more, a roll screen, in combination with a horizontal upper screen, can result in improved consistent temperature in the glasshouse. The roll screens are driven by a roller tube that rolls up the shade cloth.

For the various types of roll screen systems, we supply different types of roller tubes that are Ø 50 and 63 mm in diameter. The roller tubes are available in single and double groove sheaves. Two, simultaneously rolling, cloths can be mounted in the double-groove roller tube. This system is also called the twin roll screen system. A roll screen system is driven by tubular motors. The compact installation sizes of the tubular motor make it particularly suitable for mounting in the roller tube. The required installation space in the glasshouse remains limited, as a result. We supply two types of tubular motors varying in diameter, capacity and RPM, and can be mounted quickly. For fast assembly, we use prefab tubular motors. In this type of motor, the tubular motor is equipped with a motor tube and sealing cap.

Advantage: easier assembly of the roll screen system makes it faster to prepare for use. Pop rivets or quick-fix clamps are used to mount the coupling in the roller tube. The quick-fix clamps make drilling of holes unnecessary, but a strong attachment is guaranteed. We supply complete roll screen systems, including roll tube guides, purlin clamps and guide brackets. Our roll screen installations are available with cloth from different leading cloth suppliers.

Be the first to review “Screen System”

You must be logged in to post a review.

Reviews

There are no reviews yet.