Heating Condensors

The flue gas condenser supplied by Van Dijk heating: a success for more than 35 years now!

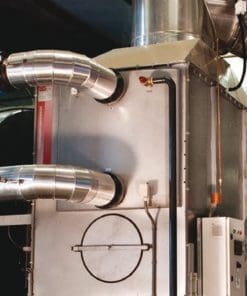

The Van Dijk heating flue gas condenser was introduced back in 1976, making it one of our oldest products. A flue gas condenser makes it possible to cool down flue gases from gas-fired equipment to a temperature below the dew point and, by doing this, utilize the condensation heat generated by the flue gases. This results in better efficiency from your burner and significant savings on your energy bill.

The flue gas condenser supplied by Van Dijk heating: a success for more than 35 years now!

The Van Dijk heating flue gas condenser was introduced back in 1976, making it one of our oldest products. A flue gas condenser makes it possible to cool down flue gases from gas-fired equipment to a temperature below the dew point and, by doing this, utilize the condensation heat generated by the flue gases. This results in better efficiency from your burner and significant savings on your energy bill. The strong construction and high quality of the materials used in the flue gas condenser guarantee a long working life and a high level of efficiency. The energy savings achieved will depend on the business situation and may be as much as 15%.

Fuel-gas side

The condenser with a built-in bypass channel is suitable for use with the flue gases produced by gaseous fuels, such as natural gas and propane. In emergencies, during which a boiler is briefly fueled with oil, the flue gases can be discharged via the bypass channel, through the flue. In the event of sustained oil firing and boiler systems that are able to switch between gas and oil fuels, a condenser without a flue-gas side bypass channel will be necessary. A valve then makes it possible to shut off the supply of flue gases to the condenser. In this system, both the boiler and the condenser are fitted with a flue (with a valve) for the discharge of

flue gases.

Water side

The condenser is available as a single condenser with one water circuit or as a combo condenser with two water circuits. It is also possible to opt to have the water side connections on the left or right-hand side. Your process data can be used to produce a heating calculation plus a related recommendation for the type of condenser and a savings calculation.

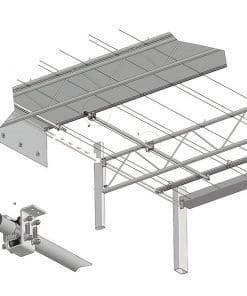

Modular construction

The Van Dijk heating flue gas condenser is available in different models: with or without a flue-gas side bypass channel and with a single or double (combo) water circuit. Because of the modular construction, Van Dijk heating is able to produce a condenser for any type of heating system. When producing a new boiler, the boiler producer welds the counter flange for the fuel-gas side connection of the condenser to the boiler. This simplifies assembly in the boiler house.

Sustainable materials

The working life achieved by a condenser will depend largely on the materials used. The flue gas condenser is made from only high-quality corten steel and aluminum. After more than 35 years,

these materials have more than proved their sustainability. Added to this, the materials are fully recyclable, making them as environmentally friendly as possible.

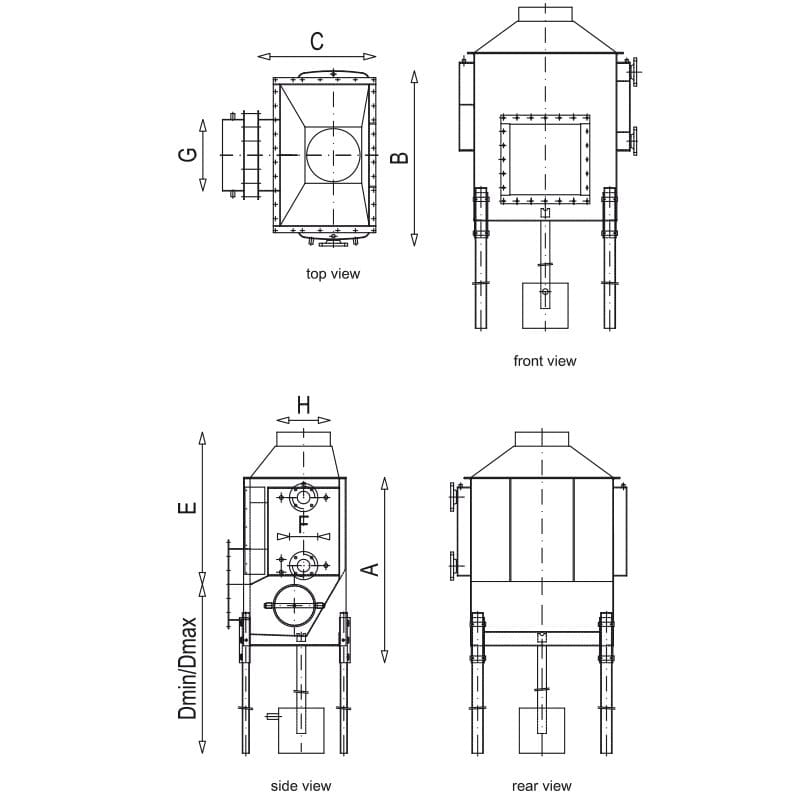

The flue gas condensor at a glance

- Proven quality and a long working life

- Sustainable construction

- Modular construction, so a solution is always possible

- Possible to use in all brands of boiler

- Good energy savings

| Type | Boiler cap. kW |

Cond. cap. kW |

Weight Empty kg |

Water cap. kg |

Dimensions | F Flanges ND6NW |

G Flue gas inlet |

H Flue gas outlet |

|||||

| A | B | C | Dmln | Dmax | E | ||||||||

| CM0501 | 580 | 82 | 230 | 60 | 1200 | 710 | 726 | 815 | 1335 | 995 | 65 | 400 | 307 |

| CM0751 | 870 | 116 | 260 | 65 | 1200 | 710 | 906 | 815 | 1335 | 995 | 65 | 400 | 377 |

| CM1001 | 1160 | 160 | 385 | 70 | 1200 | 710 | 1206 | 815 | 1335 | 995 | 65 | 400 | 377 |

| CM1501 | 1740 | 232 | 480 | 90 | 1310 | 835 | 1230 | 915 | 1435 | 1080 | 80 | 500 | 377 |

| CM2001 | 2320 | 336 | 690 | 130 | 1660 | 835 | 1230 | 915 | 1435 | 1430 | 80 | 500 | 377 |

| CM2501 | 2900 | 409 | 800 | 145 | 1660 | 865 | 1455 | 915 | 1435 | 1430 | 80 | 600 | 442 |

| CM3001 | 3480 | 498 | 1020 | 190 | 1725 | 1053 | 1466 | 970 | 1490 | 1565 | 100 | 600 | 551 |

| CM3501 | 4060 | 574 | 1190 | 205 | 1725 | 1083 | 1741 | 960 | 1480 | 1575 | 100 | 700 | 551 |

| CM4001 | 4640 | 644 | 1190 | 205 | 1725 | 1083 | 1741 | 960 | 1480 | 1575 | 100 | 700 | 551 |

| CM5001 | 5800 | 808 | 1500 | 300 | 1790 | 1460 | 1784 | 1015 | 1835 | 1585 | 125 | 800 | 551 |

| CM6001 | 6960 | 956 | 1600 | 320 | 1790 | 1460 | 2084 | 1015 | 1835 | 1660 | 150 | 800 | 600 |

| CM7501 | 8700 | 1180 | 2350 | 406 | 1850 | 1648 | 2146 | 1190 | 2170 | 1635 | 150 | 800 | 707 |

| CM8001 | 9300 | 1280 | 2530 | 419 | 1850 | 1698 | 2446 | 1215 | 2195 | 1635 | 150 | 900 | 757 |

| CM9001 | 10440 | 1420 | 2660 | 437 | 1850 | 1698 | 2446 | 1215 | 2195 | 1635 | 150 | 900 | 757 |

| CM10001 | 11600 | 1600 | 2980 | 467 | 1850 | 1698 | 2746 | 1215 | 2195 | 1635 | 150 | 900 | 757 |

| CM12501 | 14500 | 1940 | 3850 | 635 | 1910 | 2118 | 2875 | 1200 | 2240 | 1647 | 150 | 1000 | 807 |

| CM15001 | 17400 | 2220 | 3850 | 635 | 1910 | 2118 | 2875 | 1200 | 2240 | 1647 | 150 | 1000 | 807 |

Be the first to review “Heating Condensors”

You must be logged in to post a review.

Reviews

There are no reviews yet.